- Sign In

- |

- Sign Up

- |

- My Quote (0)

- |

- CART (0)

Provides exceptional accuracy for measuring torque on various products, including torque wrenches, manual screwdrivers, electric screwdrivers, pneumatic screwdrivers, and other torque controlled power tools. Features a range of 0.050 to 50 N-m and a resolution of 0.005 N-m.

Provides exceptional accuracy for measuring torque on various products, including torque wrenches, manual screwdrivers, electric screwdrivers, pneumatic screwdrivers, and other torque controlled power tools. Features a range of 0.050 to 50 N-m and a resolution of 0.005 N-m.

The torque tester provides long operation life and power flexibility with the ability to work from the internal rechargeable battery or included AC adapter. It has six modes of operation: Track for live readings, Peak which records the highest level over a test, First Peak which records a reading after a programmed decrease, Auto Peak which resets after a period of time, Auto First Peak which resets the first peak after a period of time, Double Peak which provides two separate peak readings from programmed decreases. Preset operation with programmable tolerance thresholds for quick pass-fail tool test is available in all modes.

The analog bar graph on the backlit, reversible LCD aids users by providing the resultant torque's current position compared to the full-scale range along with the direction of the force. Pass/fail icons produce live test feedback allowing instant determination of the results. Comes standard with USB and RS-232 outputs, and the software enables the uploading of data and the additional statistical analysis with its auto-calculation of the selected values.

Features

Applications

| Range (Resolution) | 0.050 to 50 (0.005) N-m 5.0 to 5000 (0.5) N-cm 0.50 to 500 (0.05) kgf-cm 0.45 to 443 (0.05) in-lbf 0.035 to 36.8 (0.005) ft-lbf |

| Accuracy | ±0.3% of reading over 5 to 100% capacity |

| Units of Measure | N-cm, N-m, in-lb, ft-lb, kg-cm |

| Measure Modes | Track, Peak, First Peak, Auto Peak, Auto First Peak & Double Peak |

| Tool Socket Size | ⅜" and ½" (10 and 12.5 mm) |

| Overload Protection | 120% of Full Scale |

| Sampling Rate | 2000 Hz |

| Peak Capture Rate | 0.05 s |

| Display | 160 x 128 Dot matrix backlit LCD |

| Display Update Rate | 10 times/sec |

| Memory | 1000 data |

| Set Point | Programmable High and Low Limits |

| Battery Indication | Battery icon flashes when low |

| Charger/Adapter | Universal USB charger, input 100 to 240 V ac 50/60 Hz |

| Operating Temperature | 14 to 104°F (-10 to 40°C) |

| Humidity Limit | 20 to 80% RH |

| Power | 3.6 V dc 1600 mAH Ni-MH |

| Battery Life | Approximately 16 Hours continuous on full charge |

| Output | USB, serial port RS-232, High and low limit NPN |

| Dimensions | Display: 7.75 x 7 x 3.3" (197 x 180 x 83 mm) |

| Weight | Display: 3.3 lbs (1.5 kg) |

| Certification | CE |

Rock climbing is a popular hobby that is growing worldwide. Indoor rock-climbing and outdoor facilities are readily found at gyms, recreation complexes, fun centers, shopping malls and various festivals. Scaling rock climbing walls is accomplished via a series of polyurethane resin grips called climbing holds. These holds come in a variety of shapes and sizes. Their form combined with relocating their mounting locations to create different patterns varies the challenge presented to the climber to ascend their way to the top.

For those that operate rock climbing walls, the holds are removed not only for creating new climbing routes, but as well for maintenance and cleaning. When the climbing holds need to be reattached to the wall, it is imperative that the mounting hardware installer mounts the holds with the proper amount of torque. Climbers depend on these holds to be stable. Over or under torquing can cause hold failure, leading to an unexpected climber fall and potential injury.

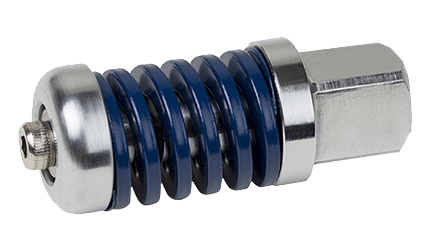

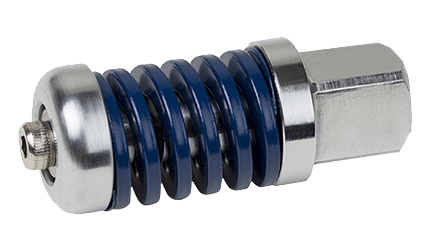

TTC-I-50 Torque Tester and coil

Utilizing the TTC-I-50 Torque Tool Tester, rock climbing operators check the performance of their equipment to verify they will apply the proper torque to the hold upon installation, ensuring correct mounting. The TTC-I-50 with 36.8 ft-lbs. (50 N-m) capacity encompasses the torque ranges required for the different size holds. Smaller size holds typically require 14.8-18.4 ft-lbs. (20-25 N-m) of installation torque, medium holds range between 18.4-25.8 ft-lbs. (25-35 N-m), while larger holds require 25.8-33.2 ft-lbs. (35-45 N-m) for proper attachment. The TTC presents the ability to store and output tool torque readings to a PC, providing accountability of the installation mounting tool's performance in the case of hold failure where injury and possible litigation may occur.

These features make the TTC the perfect device for rock-climbing operators needing consistent, dependable results for ensuring the safety of rock climbing holds and the climber enthusiasts that utilize them.

Click on a category to view a selection of compatible accessories with the SHIMPO TTC-I-50 Torque Tool Tester, 50 N-m.

| Range (Resolution) | 0.050 to 50 (0.005) N-m 5.0 to 5000 (0.5) N-cm 0.50 to 500 (0.05) kgf-cm 0.45 to 443 (0.05) in-lbf 0.035 to 36.8 (0.005) ft-lbf |

| Accuracy | ±0.3% of reading over 5 to 100% capacity |

| Units of Measure | N-cm, N-m, in-lb, ft-lb, kg-cm |

| Measure Modes | Track, Peak, First Peak, Auto Peak, Auto First Peak & Double Peak |

| Tool Socket Size | ⅜" and ½" (10 and 12.5 mm) |

| Overload Protection | 120% of Full Scale |

| Sampling Rate | 2000 Hz |

| Peak Capture Rate | 0.05 s |

| Display | 160 x 128 Dot matrix backlit LCD |

| Display Update Rate | 10 times/sec |

| Memory | 1000 data |

| Set Point | Programmable High and Low Limits |

| Battery Indication | Battery icon flashes when low |

| Charger/Adapter | Universal USB charger, input 100 to 240 V ac 50/60 Hz |

| Operating Temperature | 14 to 104°F (-10 to 40°C) |

| Humidity Limit | 20 to 80% RH |

| Power | 3.6 V dc 1600 mAH Ni-MH |

| Battery Life | Approximately 16 Hours continuous on full charge |

| Output | USB, serial port RS-232, High and low limit NPN |

| Dimensions | Display: 7.75 x 7 x 3.3" (197 x 180 x 83 mm) |

| Weight | Display: 3.3 lbs (1.5 kg) |

| Certification | CE |

Rock climbing is a popular hobby that is growing worldwide. Indoor rock-climbing and outdoor facilities are readily found at gyms, recreation complexes, fun centers, shopping malls and various festivals. Scaling rock climbing walls is accomplished via a series of polyurethane resin grips called climbing holds. These holds come in a variety of shapes and sizes. Their form combined with relocating their mounting locations to create different patterns varies the challenge presented to the climber to ascend their way to the top.

For those that operate rock climbing walls, the holds are removed not only for creating new climbing routes, but as well for maintenance and cleaning. When the climbing holds need to be reattached to the wall, it is imperative that the mounting hardware installer mounts the holds with the proper amount of torque. Climbers depend on these holds to be stable. Over or under torquing can cause hold failure, leading to an unexpected climber fall and potential injury.

TTC-I-50 Torque Tester and coil

Utilizing the TTC-I-50 Torque Tool Tester, rock climbing operators check the performance of their equipment to verify they will apply the proper torque to the hold upon installation, ensuring correct mounting. The TTC-I-50 with 36.8 ft-lbs. (50 N-m) capacity encompasses the torque ranges required for the different size holds. Smaller size holds typically require 14.8-18.4 ft-lbs. (20-25 N-m) of installation torque, medium holds range between 18.4-25.8 ft-lbs. (25-35 N-m), while larger holds require 25.8-33.2 ft-lbs. (35-45 N-m) for proper attachment. The TTC presents the ability to store and output tool torque readings to a PC, providing accountability of the installation mounting tool's performance in the case of hold failure where injury and possible litigation may occur.

These features make the TTC the perfect device for rock-climbing operators needing consistent, dependable results for ensuring the safety of rock climbing holds and the climber enthusiasts that utilize them.

Click on a category to view a selection of compatible accessories with the SHIMPO TTC-I-50 Torque Tool Tester, 50 N-m.